In the quiet corners of material science laboratories, a silent revolution is brewing, one that grows rather than is manufactured. Researchers and innovators are increasingly turning their attention to the humble yet astonishing world of fungi, specifically the root-like network known as mycelium, to develop sustainable building materials. Among the most promising applications is the creation of fully biodegradable acoustic insulation panels, a development that could significantly alter the environmental footprint of the construction industry.

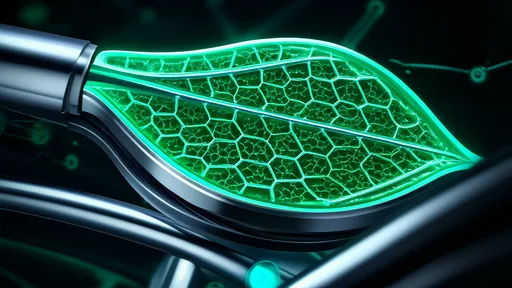

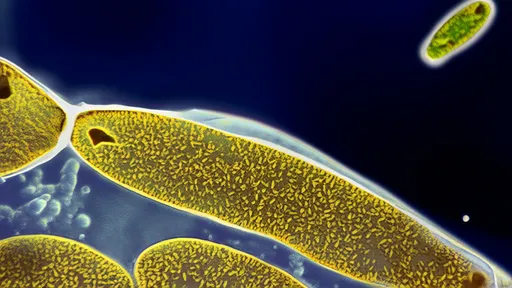

The core of this innovation lies in the unique properties of mycelium, the vegetative part of a fungus. This intricate web of hyphae acts as a natural binder, a self-assembling glue that can be trained to grow around a substrate of agricultural waste, such as straw, wood chips, or even cotton burrs. Under controlled conditions, this fungal network colonizes the substrate, weaving through it and binding it into a solid, cohesive mat. Once the growth process is complete, the material is heat-treated to stop further growth, resulting in a sturdy, lightweight, and surprisingly robust block. This block can then be cut and shaped into panels of various sizes and densities.

The drive toward mycelium-based materials is not merely a scientific curiosity; it is a direct and urgent response to the escalating environmental crisis fueled by conventional construction practices. The building sector is notoriously resource-intensive, accounting for a staggering portion of global energy consumption, waste production, and carbon emissions. Traditional insulation materials, like fiberglass or foam plastics, are derived from petrochemicals, are energy-intensive to produce, and present a monumental waste problem at the end of a building's life, often languishing in landfills for centuries. Mycelium panels offer a powerful antidote to this linear and wasteful model. They are grown, not made, requiring minimal energy input. They transform low-value agricultural byproducts into high-value materials, and at the end of their useful life, they can be simply composted, returning nutrients to the soil and completing a beautiful, circular lifecycle.

Perhaps the most compelling feature of mycelium insulation, beyond its sustainability credentials, is its innate and exceptional acoustic performance. The very structure that makes mycelium so effective is a natural sound dampener. The dense, interwoven, and porous matrix of hyphae is exceptionally effective at trapping sound waves. As sound energy travels through the panel, it is forced through a labyrinth of tiny tunnels and chambers. This journey causes friction, which converts the acoustic energy into negligible amounts of heat energy, thereby absorbing the sound. This natural mechanism rivals and often surpasses the performance of many synthetic acoustic tiles and foams, making it a superior choice for creating quieter, more serene interior environments in offices, homes, studios, and commercial spaces.

The journey from a petri dish to a commercially viable product is, however, filled with challenges that scientists and entrepreneurs are diligently working to overcome. Scaling up production from small laboratory samples to industrial-scale manufacturing requires sophisticated bioreactors and precise environmental control to ensure consistent quality and properties in every batch. Questions regarding long-term performance in varied climates—resistance to moisture, fire retardancy, and structural integrity over decades—are the focus of ongoing research and testing. Furthermore, navigating building codes and convincing a traditionally conservative industry to adopt a living material requires not just data, but a fundamental shift in perspective, viewing buildings not as static structures but as dynamic, biological entities.

Despite these hurdles, the future for mycelium insulation appears bright and is already taking root in the real world. A growing number of forward-thinking architects and developers are incorporating these bio-based panels into their projects, championing them as a cornerstone of regenerative design. Companies dedicated to perfecting the production and distribution of mycelium materials are emerging, attracting significant investment and pushing the boundaries of what's possible. The vision extends far beyond simple flat panels; researchers are exploring growing mycelium into specific shapes, even creating self-supporting structures, pushing the boundaries of bio-fabrication into the realm of architectural form.

The development of mycelium-based acoustic panels is far more than a niche innovation in material science. It represents a profound paradigm shift in how we conceive of, create, and dispose of the materials that shape our world. It moves us away from an extractive and polluting industrial model and toward a future that is harmonious with nature, one where we cultivate our resources. This is not just about building quieter spaces; it is about forging a new, quieter pact with our planet, one grown from the ground up.

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025

By /Aug 27, 2025