The global push for sustainable protein sources has led researchers to explore unconventional yet remarkably efficient biological systems. Among these, microalgae photobioreactors have emerged as a particularly promising technology, not merely for their protein production capabilities but for their unique dual function in wastewater treatment and resource valorization. This innovative approach represents a paradigm shift in how we view both waste management and food production, transforming environmental challenges into economic opportunities.

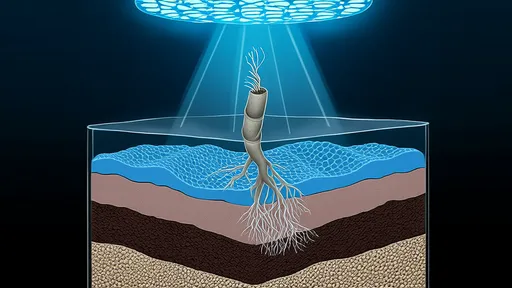

Microalgae, the microscopic photosynthetic organisms at the heart of this technology, possess an extraordinary ability to thrive in nutrient-rich wastewater while simultaneously purifying it. These tiny powerhouses consume nitrogen, phosphorus, and other contaminants present in wastewater, effectively cleaning the water while converting these "waste" nutrients into valuable cellular components. The resulting biomass is exceptionally rich in proteins, often containing 40-60% protein by dry weight, along with valuable lipids, carbohydrates, and pigments. This process creates a circular economy model where waste streams become valuable feedstocks for high-quality protein production.

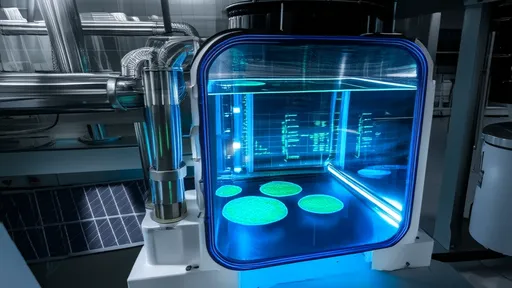

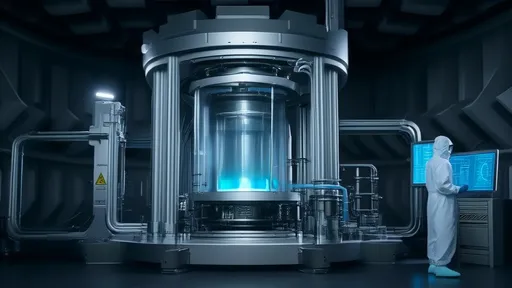

The engineering behind modern photobioreactors has evolved significantly from simple open ponds to sophisticated closed systems that optimize growth conditions. These advanced systems precisely control temperature, light intensity, pH, and gas exchange to maximize algal growth rates and protein content. Unlike traditional wastewater treatment plants that consume energy to remove nutrients, these bioreactors actually generate valuable biomass while performing treatment. The closed-system design prevents contamination, allows for year-round operation, and eliminates water loss through evaporation, making it particularly valuable in water-scarce regions.

What makes this approach truly revolutionary is its economic viability. While conventional wastewater treatment represents a cost center for municipalities and industries, microalgae systems transform this equation by creating valuable products from waste nutrients. The produced algal biomass can be processed into various high-value products including protein concentrates for animal feed, nutritional supplements for human consumption, biofuels, and specialty chemicals. This creates multiple revenue streams that can offset and potentially exceed operational costs, making wastewater treatment economically sustainable rather than burdensome.

The protein quality from microalgae is another remarkable aspect of this technology. Many algal species contain all essential amino acids in proportions that meet or exceed FAO requirements, making them complete protein sources. Furthermore, microalgae proteins often demonstrate excellent digestibility and functional properties suitable for food applications. Species like Spirulina and Chlorella have already gained regulatory approval for human consumption in many countries, paving the way for broader adoption of algal proteins in the food industry.

Environmental benefits extend beyond wastewater treatment. Microalgae cultivation in photobioreactors consumes carbon dioxide during photosynthesis, potentially capturing emissions from industrial facilities when integrated with flue gases. This carbon capture capability adds another environmental dimension to the technology's sustainability profile. Additionally, compared to traditional agriculture, algal protein production requires significantly less land and water per unit of protein produced, addressing two critical constraints in conventional food production systems.

Implementation challenges remain, particularly regarding scaling and economic optimization at commercial levels. While laboratory and pilot-scale studies demonstrate impressive results, translating these to large-scale operations requires careful engineering and economic planning. Harvesting and processing the algal biomass efficiently represents another technical challenge that researchers continue to address through innovations in centrifugation, filtration, and flocculation technologies. Energy inputs for mixing, gas exchange, and harvesting need optimization to ensure net positive energy balance.

Despite these challenges, several successful implementations already demonstrate the technology's potential. Various projects worldwide have integrated microalgae systems with municipal wastewater treatment plants, agricultural runoff management, and industrial effluent treatment. These installations not only improve water quality but generate additional revenue through biomass sales. The integration with existing infrastructure often proves more feasible than standalone systems, leveraging established wastewater collection and handling systems while adding the valorization component.

Market acceptance of algal products continues to grow as consumers increasingly seek sustainable and plant-based protein alternatives. The animal feed industry represents a particularly promising market, where algal proteins can replace fishmeal or soybean meal while providing additional nutritional benefits. Human nutrition markets show growing interest in algal ingredients for protein supplements, meat alternatives, and functional foods. This market pull creates economic incentives for further development and deployment of microalgae wastewater treatment systems.

Research continues to enhance the efficiency and economics of these systems. Genetic engineering approaches aim to develop algal strains with higher protein content, better growth rates, and enhanced tolerance to varying wastewater compositions. Process engineering innovations focus on reducing energy consumption and improving nutrient utilization efficiency. Integration with other waste streams, such as agricultural residues or food processing waste, creates additional synergies and value opportunities.

The regulatory landscape is gradually adapting to accommodate these innovative systems. As evidence of safety and efficacy accumulates, regulatory agencies are developing frameworks for approving algal products from wastewater-grown biomass. This regulatory evolution is crucial for market access and consumer confidence. Standardization of quality parameters and processing methods will further facilitate market development and technology adoption.

Looking forward, microalgae photobioreactors represent more than just a technological innovation—they embody a fundamental shift toward circular economy principles in waste management and food production. By transforming wastewater from an environmental liability into a valuable resource, these systems address multiple sustainability challenges simultaneously. As technology advances and scale increases, we can anticipate broader adoption across various sectors, ultimately contributing to more sustainable water management, reduced environmental impact, and enhanced food security.

The convergence of environmental necessity and economic opportunity makes microalgae-based wastewater valorization particularly compelling. In a world facing increasing pressure on water resources, nutrient pollution, and protein demand, this technology offers integrated solutions that address these challenges while creating economic value. The continued development and deployment of these systems will likely play an important role in building more sustainable and resilient food and water systems for the future.

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025