In a groundbreaking development that promises to redefine the future of transportation, engineers and researchers have achieved a significant breakthrough in the aerodynamic optimization of vacuum maglev logistics systems, specifically designed for intercity capsule transport. This innovation addresses one of the most critical challenges in high-speed vacuum tube travel: minimizing air resistance to achieve unprecedented efficiency and speed. The implications for global logistics, urban connectivity, and sustainable transport are profound, potentially heralding a new era where goods and people move between cities at near-supersonic speeds with minimal energy consumption.

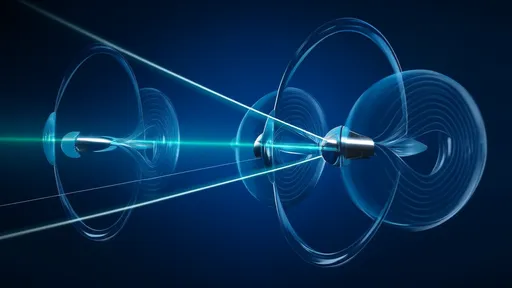

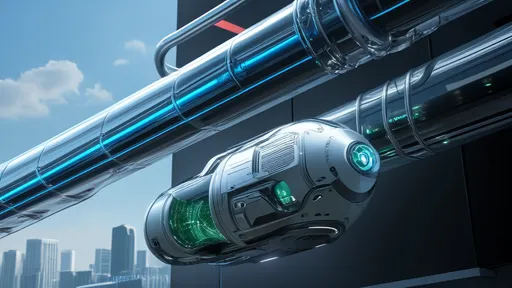

The core of this advancement lies in the meticulous redesign of the capsule's aerodynamic profile. Traditional high-speed vehicles, even in low-pressure environments, face drag forces that escalate exponentially with velocity. By employing computational fluid dynamics simulations and wind tunnel testing under vacuum conditions, researchers have developed a capsule shape that drastically reduces drag coefficients. The optimized design features a elongated nose cone, smoothly contoured body, and a tapered tail, all engineered to manage airflow and pressure gradients with exceptional precision. This design not only enhances speed but also improves energy efficiency, reducing the power required to maintain levitation and propulsion within the magnetic fields.

Another pivotal aspect of this optimization is the integration of active aerodynamic controls. Unlike passive designs, these systems use real-time sensors and micro-adjustable surfaces on the capsule exterior to adapt to varying conditions within the tube. For instance, during acceleration or deceleration phases, small fins or surfaces can deploy minutely to optimize airflow, preventing turbulence and maintaining stability. This dynamic approach ensures that aerodynamic efficiency is preserved across different operational scenarios, from cruising at top speed to navigating slight curves in the tube network. Such adaptability is crucial for the practical deployment of these systems in diverse geographical terrains.

The vacuum environment itself plays a dual role: while it eliminates most air resistance, it introduces unique challenges related to pressure management and thermal effects. The optimized system includes advanced sealing technologies and pressure regulation mechanisms to maintain a near-perfect vacuum along extensive tube sections. Additionally, the aerodynamic design accounts for thermal expansion and contraction of materials under variable conditions, ensuring structural integrity and consistent performance. These considerations are vital for the safety and reliability of intercity capsules, which must operate flawlessly over long distances without frequent maintenance.

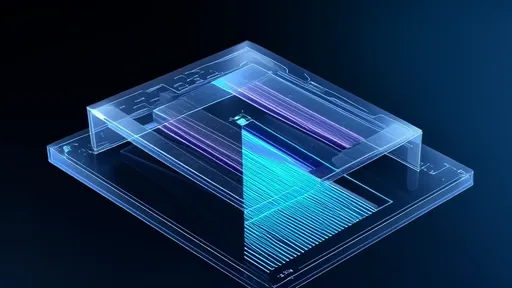

Beyond the capsules, the tube infrastructure has also undergone aerodynamic refinement. The interior surfaces of the tubes are engineered with ultra-smooth materials and precise geometries to minimize any residual drag from the thin atmosphere. Innovations in magnetic levitation and propulsion systems synergize with these aerodynamic improvements, allowing capsules to achieve speeds previously thought unattainable for ground transport. Early prototypes in test facilities have demonstrated sustained speeds exceeding 1,000 kilometers per hour, with simulations suggesting potential for even higher velocities as optimization continues.

The economic and environmental benefits of this optimized system are staggering. By drastically reducing energy consumption per ton-kilometer of transport, vacuum maglev logistics could slash the carbon footprint of freight and passenger movement between urban centers. Cities could become more interconnected without the sprawl of highways or airports, reducing land use and noise pollution. Moreover, the speed and efficiency could revolutionize supply chains, enabling just-in-time delivery across regions and boosting economic productivity. Investors and governments are taking note, with several pilot projects slated for development in technologically advanced regions.

However, challenges remain on the path to widespread adoption. The initial capital investment for infrastructure is substantial, requiring extensive tunneling or elevated tube networks. Regulatory frameworks and safety standards must be established to govern these high-speed systems, particularly concerning emergency scenarios and public acceptance. Despite these hurdles, the progress in aerodynamic optimization marks a critical milestone, proving that the technical barriers are surmountable with continued innovation and collaboration across disciplines.

Looking ahead, the next phase of research focuses on scaling these optimizations for larger capsules and longer routes, as well as integrating renewable energy sources to power the entire system. The vision of a global network of vacuum maglev tubes, where capsules glide silently and efficiently between cities, is inching closer to reality. As this technology evolves, it may well become the backbone of twenty-first-century transportation, transforming how we perceive distance and connectivity in an increasingly urbanized world.

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025